Client Profile:

BSD Industries is Chicago’s newest Registered Apprenticeship Program sponsor. They will launch three programs this summer.

BSD submitted their RAP applications to the Department of Labor earlier this year with assistance from RADD Training and the Illinois Manufacturing Excellence Center (IMEC), which helps manufacturers make connections and provides guidance, support, and resources to improve operations and profitability. After months of work, the DOL recently approved their sponsorship.

The three RAPs will upskill apprentices of nearby employer partners. This is significant, in part, because BSD is helping to meet local workforce development needs. Additionally, the apprenticeship programs will “build confidence in the [local] manufacturing community,” says Trista Bonds, BSD Industries Vice President of Engineering and Manufacturing Operations.

Building confidence is what BSD Industries does best. Yes, they manufacture a range of high quality, sustainable, plastic products, but their mission is really about the people. In fact, BSD stands for Building Self Determination because they want to develop students and support them in securing careers through the “earn and learn” apprenticeship model.

Photo provided by Trista Bonds

BSD apprentices complete their Related Training coursework on site with the company’s in-house certified instructors. They earn college credit at Daley College. Along with their Department of Labor credential at the close of the programs, apprentices earn a couple of interim certificates along the way. They complete their On-the-Job Training hours with employer partners.

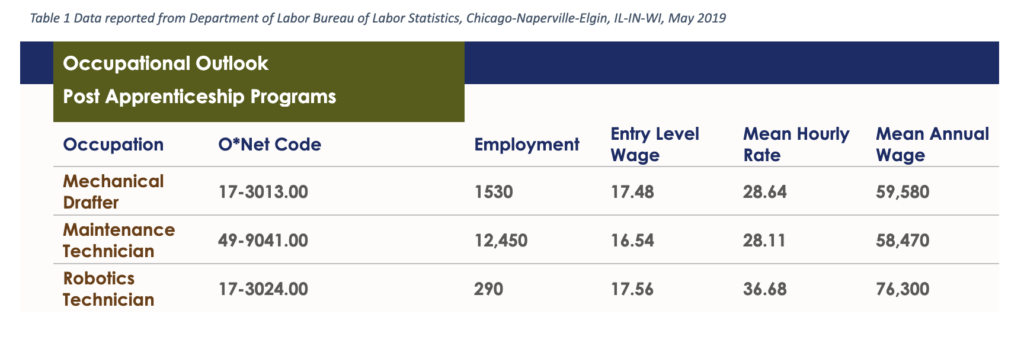

In the following Q&A with Trista Bonds, learn more about the steps BSD took to complete the RAP applications for the CAD Drafting, Maintenance Technician, and Robotics Technician occupations.

Note: Trista’s responses are paraphrased.

How did you first learn about the opportunity to become a Registered Apprenticeship Program sponsor?

When we first opened BSD in 2017 and we were trying to figure out what accreditations were available, we came across the Department of Labor website. The DOL oversees Registered Apprenticeship Programs. We also learned about the Illinois Board of Higher Education and how the option of earning college credit might impact our programs.

Nikki Bravo, BSD Vice President; Dr. Byron T. Brazier, whose Brazier Foundation supports BSD; and I met with Jim Nelson from the Illinois Manufacturers’ Association. He sat us down and gave us the lay of the land. We also talked to Kim Jones, State Director of the Department of Labor’s Office of Apprenticeship.

After a couple of years of being in operation, we re-initiated the conversation with IMEC, who introduced us to Rebecca Daurio of RADD Training.

Why did becoming a Registered Apprenticeship Program sponsor appeal to BSD Industries?

In seeking accreditation, we wanted to make sure we were following established standards and being monitored by a nationally-accredited institution like the Department of Labor. Our intention was to offer the best possible training for our students and participants. We wanted to take the right path to build confidence in our students and also be held to the highest standards as an organization.

Why those three specific apprenticeship tracks?

We were interested in maintenance because most of our graduates [prior to the Registered Apprenticeship Program] were in maintenance roles. We saw a greater demand in the industry for maintenance-type skill sets.

I have a strong passion for robotics and believe it’s a vital and essential skill. It may not be as in high demand at this point, but I think it will be as companies robotize their facilities. Some view robotics as taking jobs away; I wanted to be on the side of training people for those skills so they would not lose an opportunity.

What are your goals as a Registered Apprenticeship Program sponsor?

At the end of the day, we hope to secure the confidence of our employer partners. They need highly skilled individuals, and we want to place our apprentices in their programs. In general, we want to build confidence in the manufacturing community. What better way than by showcasing a “DOL” seal on our apprentices’ certificates?

As you were developing the RAPs, what were BSD’s strengths?

For the Related Instruction component of the application, all of our curriculum was already designed and approved by the IBHE. Our partner, Daley College, also was following the pathway to becoming a RAP. We were able to synchronize some of our efforts and curriculum, because we offer dual credit through Daley College.

In what areas, if any, did BSD have deficits / challenges related to RAP development? How did you address those?

The first challenge was adjusting our On-the-Job Training hours so we could meet DOL requirements of 2,000 hours per year, or 6,000 hours total for our three-year programs. In our earlier discussions, the minimum criteria was for fewer hours. Because of that moving target, we had to be creative to avoid tearing down what we already established in our curriculum. We decided to add Manufacturing Skill Standards Council topics to OJT, such as safety, quality, and process control. This would strengthen the candidates’ training and proficiency of skills without intruding on the On-the-Job Training component.

Talk about your apprentices. How will you recruit them? How many do you expect will enroll in your cohorts on an annual basis? What will BSD do to ensure their success throughout the program?

Photo provided by Trista Bonds

We recruit in a variety of ways: through the Chicago Housing Authority, internal and external information sessions, and through training provider partners. In the future, we hope to tap into our employer partners as well as high schools, where we potentially could offer dual credit.

As for numbers, we have a conservative approach. We hope to have a smaller cohort of about 10-12 starting in 2020. BSD wants to make sure we get it right and achieve at least a 50-70 percent success rate.

One way we will ensure the success of our apprentices is by providing them with a qualified mentor. We also will support them by continuing to offer a weekly colloquium every Friday. During that time, students come together for career development and maintenance workshops, among other topics. Sometimes we have guest speakers sharing industry stories of success for rising maintenance and robotics techs.

How have your partnerships contributed to the success / ease of the RAP application process and, now, the implementation?

In addition to the partners previously mentioned, we recently had our first discussion with the Bureau of Economic Development about what the approach would look like for BSD and our design for our apprenticeship infrastructure. Our focus is on growth and talent need. One of their staff members has a lot of experience with social ventures and enterprises, training institutions, and specifically infrastructure design. She will help us to manage recruitment, an employment tracking database, and determine how to assess skills. We want to have a metric for the employers to follow.

What makes you most proud about your RAPs?

I am most proud that we can see transformation. We can see self determination becoming a reality for a lot of our candidates, and we have seen it from all age groups. We’ve had some students with great opportunities to become supervisors, sales representatives, technicians… The greatest rewards are the outcomes.

What advice would you offer to others aspiring to become a Registered Apprenticeship Program sponsor?

Clear your perceptions and assumptions and start with a blank slate. There’s so many things you don’t really know, and you don’t want to make assumptions before you know the requirements for your industry. When you start with a blank slate, it’s easier to evaluate all of the pieces you’ve developed internally and fit them into the framework that DOL requires.

Also, have a good resource to guide you through the process, an expert who knows the DOL system and takes the time to learn your organization and program. Someone like Rebecca Daurio of RADD Training. She showed us what we already had in place and helped us put them in order so we were able to move forward.

Finally, have strong employment partners — commitment and buy-in from sources where you can actually place those apprentices. Or, make sure you have the capacity internally to provide the right kind of work for them. The work has to align with the skills they are learning.

Anything else you’d like to add?

I’m excited, happy, and nervous all at the same time. We’re reporting to the DOL on our outcomes; it’s a very high-stakes, highly visible position to find ourselves in. But it’s a good thing. I want to make sure we can deliver.

Recent Comments